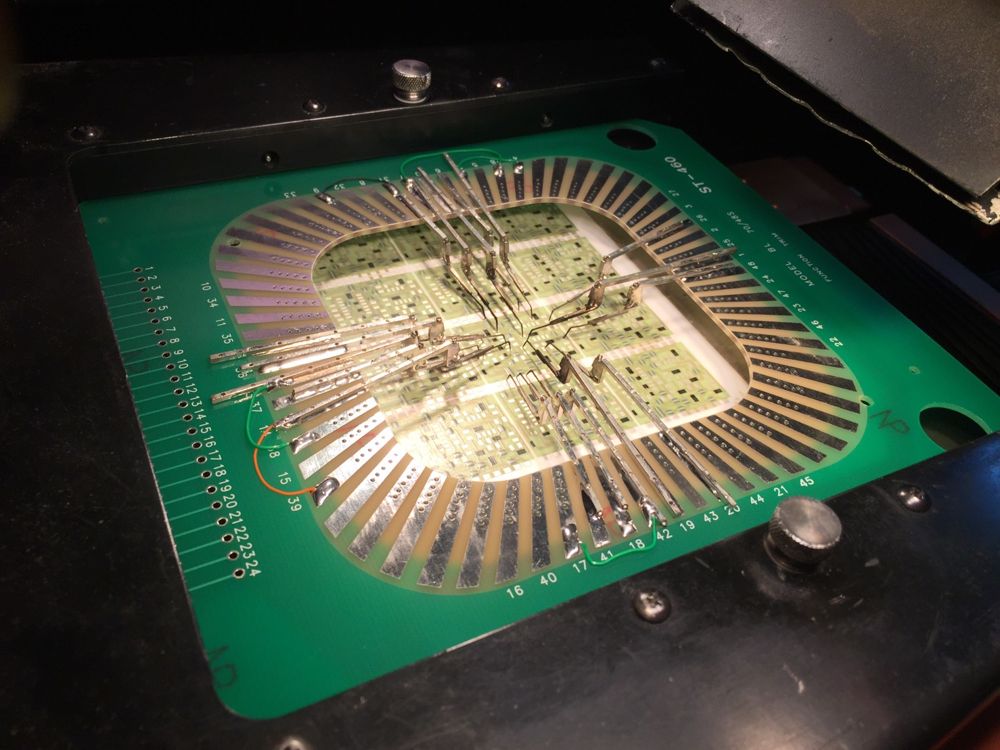

Resistor Active Laser Trimming

Laser trimming plays an important and essential role in Thick-film resistor networks, is fast and inexpensive. This manufacturing process can adjust the resistance of thick film printed resistor for custom design.

Laser standard

- MIL-STD863G (United States Military Standard)

- Laser trimming precision:±0.1% Resistance

Laser Trimming Specification

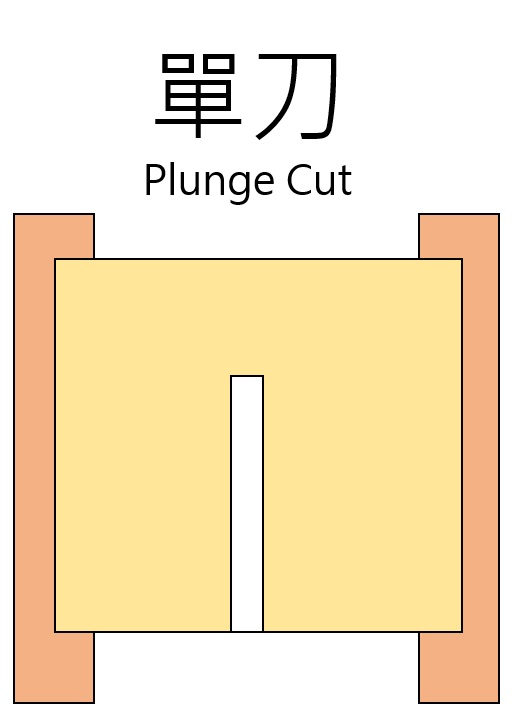

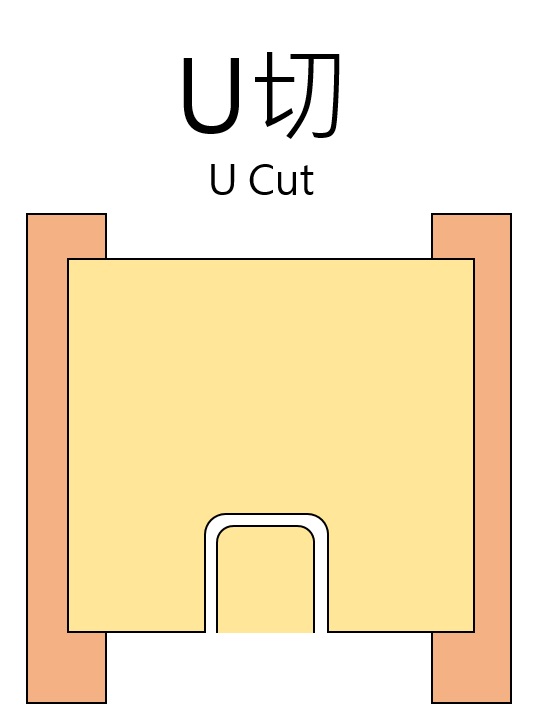

Most cost effective and simplistic

Most cost effective and simplistic

Minimum Precision

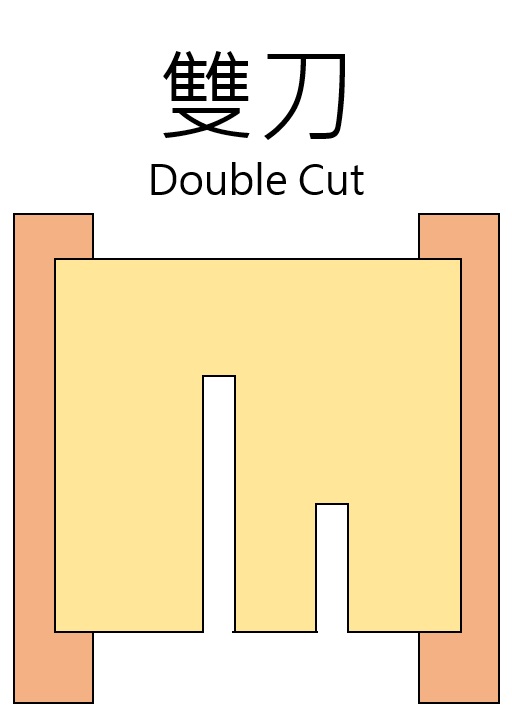

Trimming efficiency is lower than plunge cut

Trimming efficiency is lower than plunge cut

Precision is higher than plunge cut

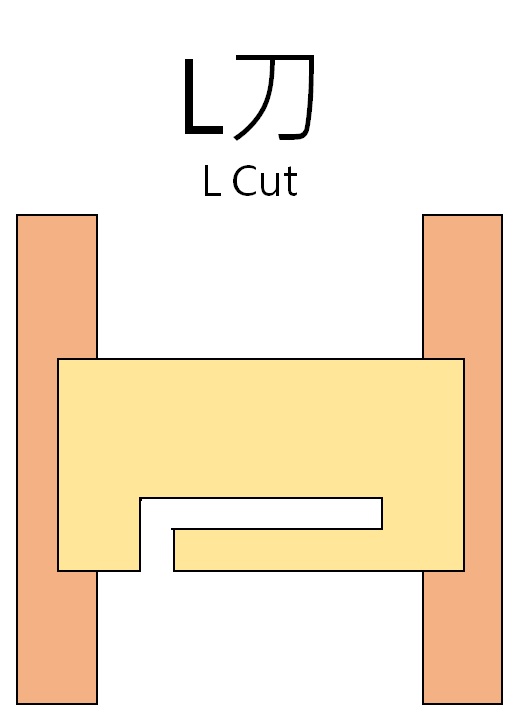

L cut is used most often

L cut is used most often

Has good stability and accuracy

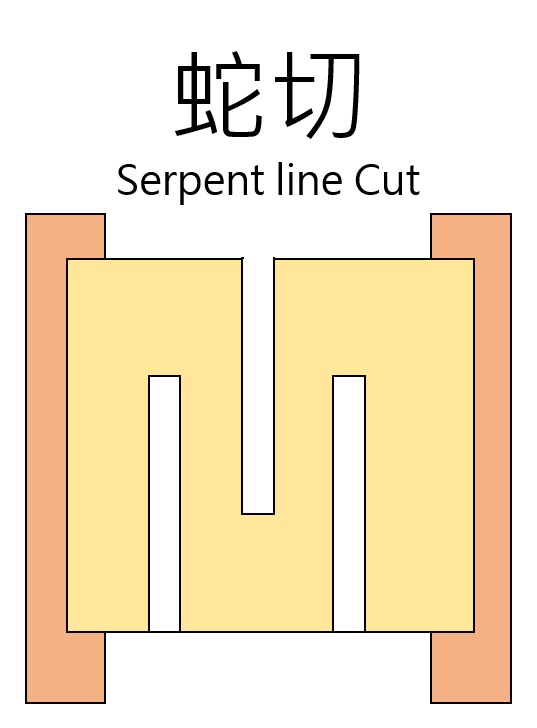

Serpent line cut usually used in trimming if pre-trimming resistance value is much lower than the targeted value

Serpent line cut usually used in trimming if pre-trimming resistance value is much lower than the targeted value

Used for high accuracy trimming

Used for high accuracy trimming

Low trimming efficiency but high stability

Total Quality Control

- 100% Visual Inspection