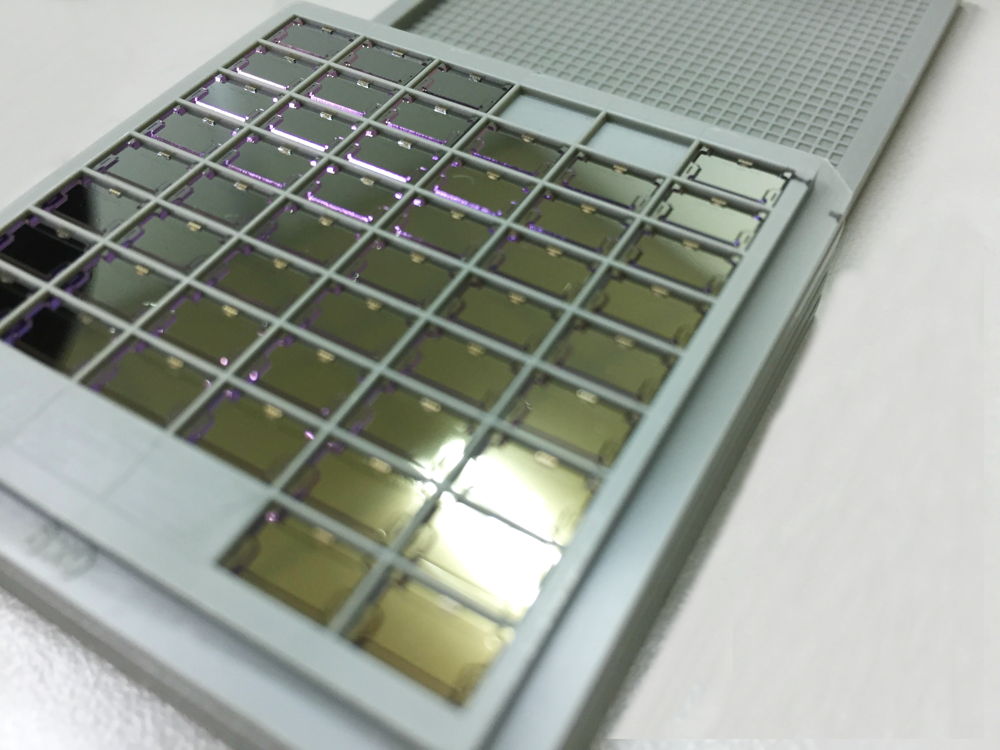

Chip On Board

Chip on board, or COB process consists of three major steps: 1. Die attachment or Die mount 2. Wire Bonding and 3. Encapsulation of the die and wire.

Die Bonding Capability

- Chip Dimension:0.15* 0.15 mm ~ 100* 100 mm

- Repeat Accuracy:±33 um

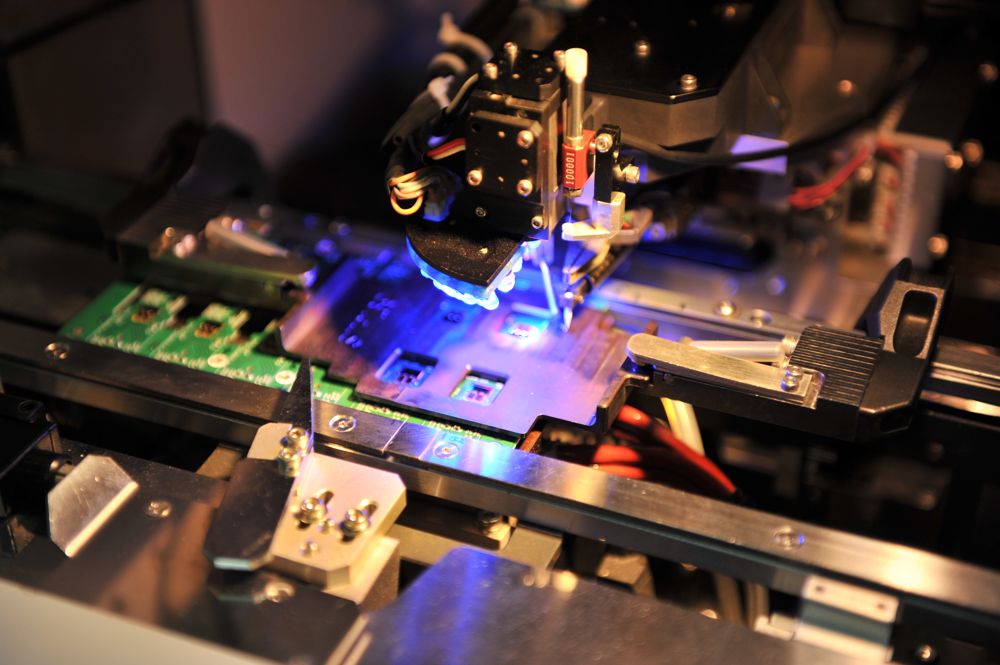

Wire Bonding Capability

- Au wire:0.7 mil ~ 1.2mil

- Au wire repeat accuracy:±2.5 um

- Minimum Fine Pitch:35 um

- Al wire:0.7 mil ~ 2.0 mil, 5mil ~12 mil

- Al wire :±2.5 um

1K class Clean-booth environment

- Clean suit

- Anti-static wrist straps

Totally quality management

- 100% Visual Inspection

- Wire pull-out test

- Stereo Microscope / Lamp10X